Print

Products Routing Underlays Routing Underlay Vilmill

Routing Underlay Vilmill

vilmill™- Technology - applications

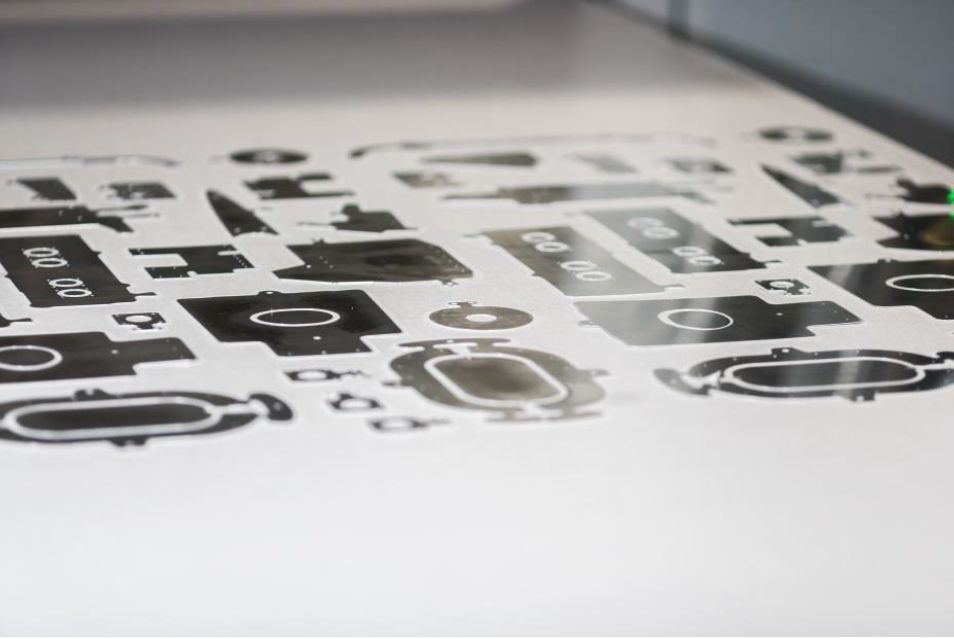

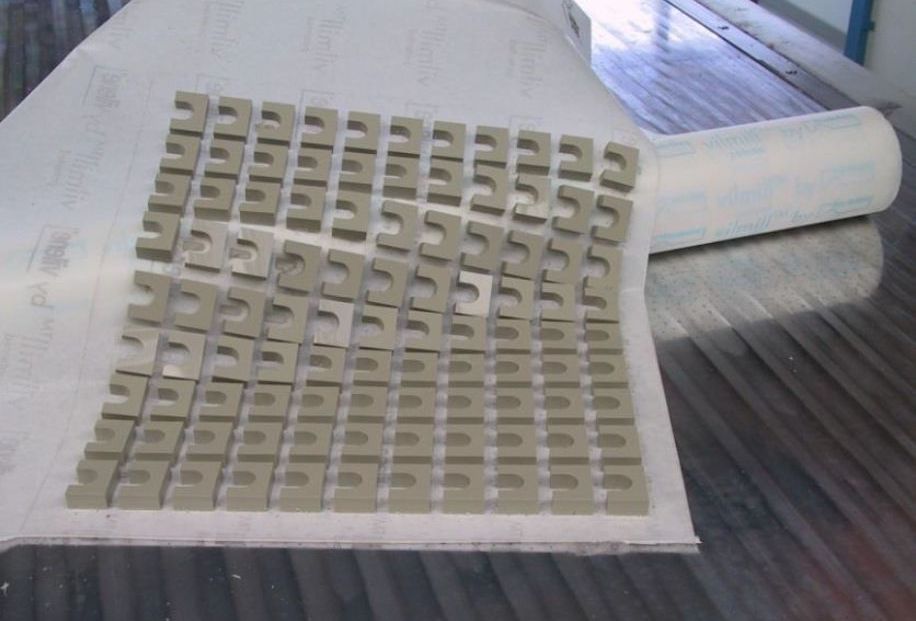

vilmill™- Routing Underlay on vacuum tables for safe holding of small parts during the cutting of thin sheets and plates made of aluminum and plastics.

vilmill™- Technology - advantages

- the Vilmill underlay is placed between the vacuum table and the workpiece

- thanks to its optimized adhesive layer, it guarantees the reliable fixing of filigree parts thus increases process reliability

- significantly higher feed rates can be achieved

- the heat generated during the processing at the milling edge leads to their embedding by melting the surface of vilmill™.

- additional work can be omitted

- furthermore, vilmill ™ supports the removal of milling parts and residual lattice to a removal table

- efficient use of expensive semi-finished products through close nesting

- expensive tool costs can be saved

Vilmill Blue

vilmill™- blue - Routing Underlay on vacuum tables for safe holding of small parts during the cutting of plates made of aluminum and plastics.

Vilmill Black

vilmill™- black - with optimized adhesive layer for safe holding of small parts during the cutting of plates made of aluminum and plastics.